Finally. A modern solution to address

Retailers face countless roadblocks as they try to achieve the faster deliveries that

customers demand. Fabric micro-fulfillment makes those challenges a thing of the past.

Leverage a local footprint, dense storage, and urban

locations to shrink lead times and maximize customer

satisfaction.

The Fabric MFC® is:

Local

Stand up fulfillment operations

in urban areas.

Our system is designed for speed and efficiency. Slash last

mile delivery costs and times by storing your inventory closer

to your customers.

Small

Flexible, high density storage.

Circumvent real estate limitations and high costs. Our 3D

storage model is flexible enough to fit into any footprint, no

matter the size, shape, or structural design constraints.

Automated

Software-driven robotics for reliability

and efficiency.

Our system is more flexible and reliable. Increase efficiency

and throughput while reducing your cost and reliance on the

unstable labor market.

A complete solution, designed to deliver:

3x

increased throughput compared to manual fulfillment

85%

In overhead cost savings

70%

Improvement in storage density

99%

Inventory accuracy

The Fabric Smart Cube:

High-density robotic fulfillment enabled by Fabric software and AI, unlocks

instantaneous capacity, system reliability and high efficiency throughput.

High Density

Storage

Fabric’s highly flexible cube topology can fit into almost any existing space, large or small.

Warehouse Management System

Allows clients to control and administer their warehouse operations from the time goods enter their warehouse until they move out.

Fabric Fulfillment Intelligence

AI engine that maximizes automation performance by prioritizing, planning and executing all fulfillment tasks within the automation.

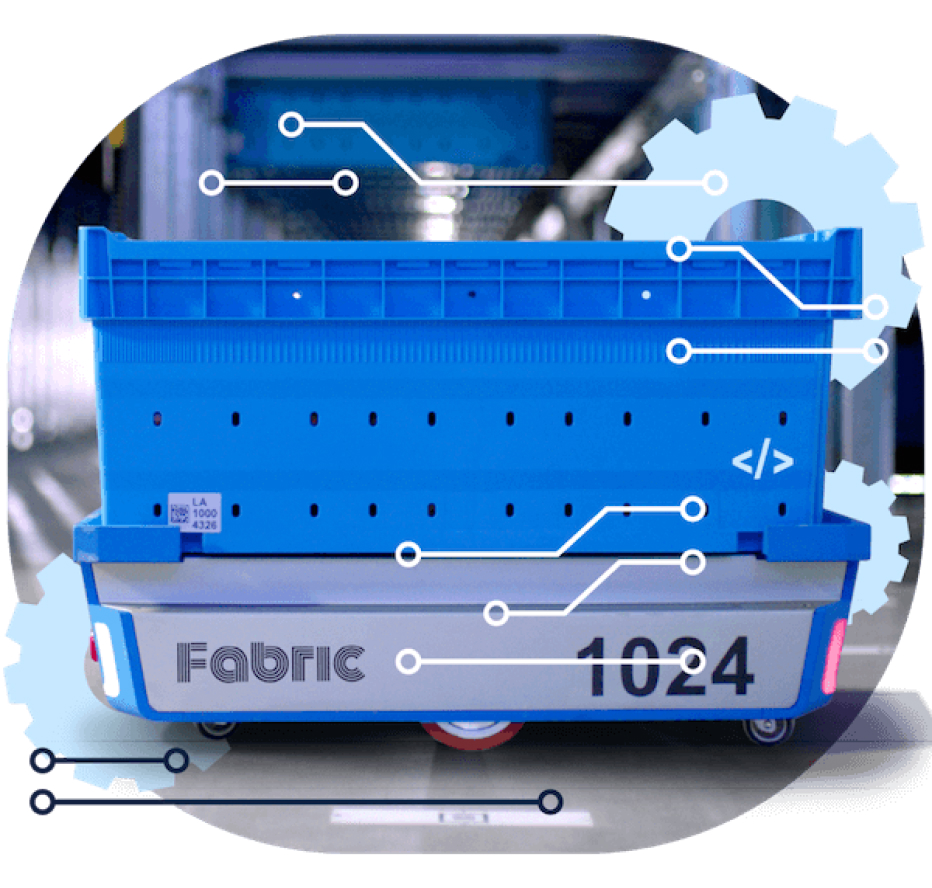

Our Robots are software-driven and

housed in a distributed system for

maximum reliability and up-time.

Lift Robot

Lift robots pull totes with inventory from our 3D storage unit, then pass the totes to the ground robot.

Ground Robot

Ground robots transport the totes, and line them up in an optimized sequence and are carried to the touchpoint for order packing. They also carry completed-order totes to be dispatched for delivery.

Touchpoint

Fabric touch points are designed for order picking and inventory decanting, optimizing your footprint. Operators are given detailed on-screen instructions to support each task.

See how micro-fulfillment is done the Fabric way

Schedule a Tour

Take a look inside our MFC®s from the comfort and convenience of your desk, or come visit us on-site.